What if your everyday care products were alive, therapeutic and regenerative?

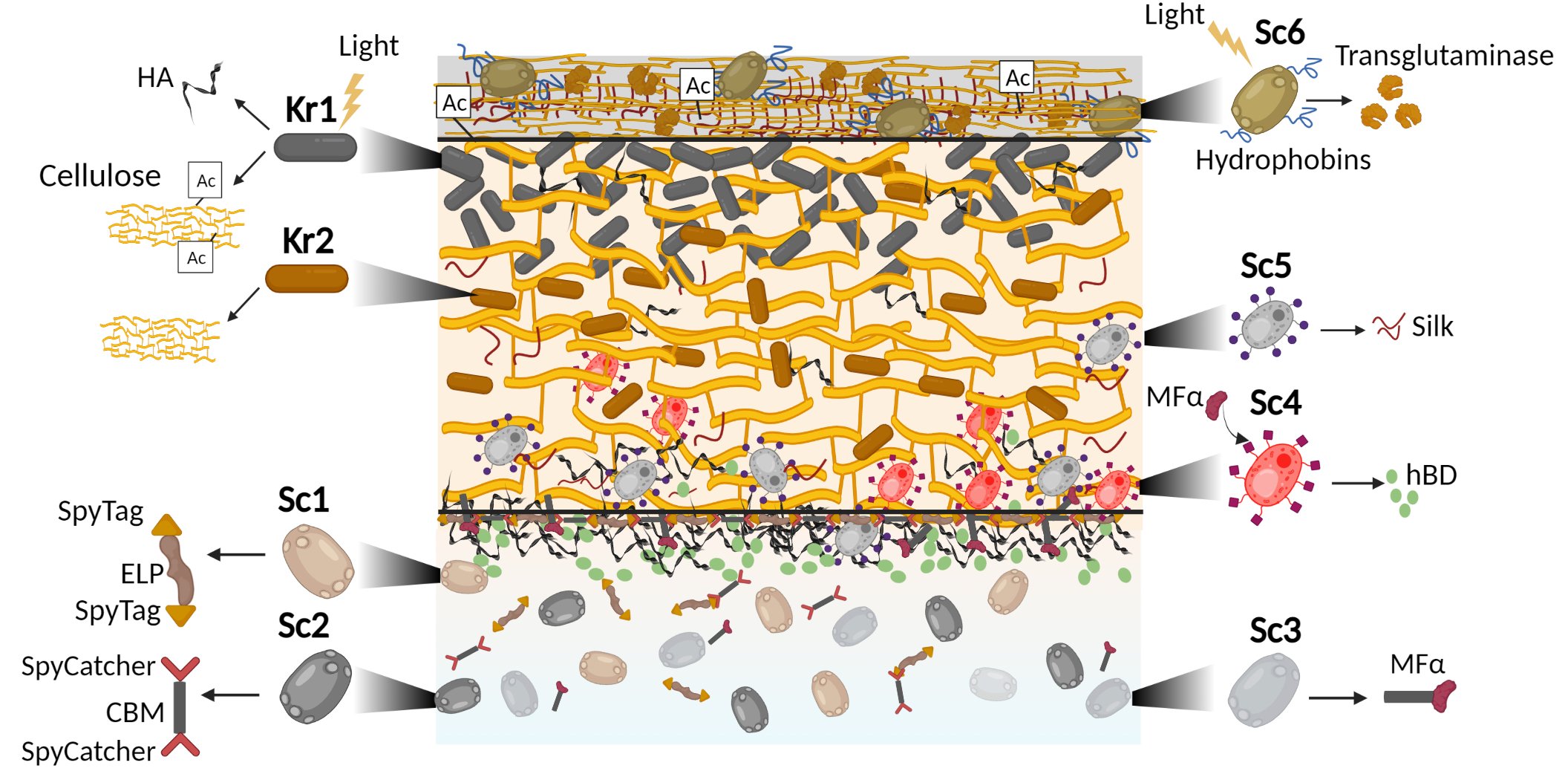

NextSkins creates new living interfaces composed of layers with dedicated, specialised functions including protection, sensing, mechanical strength, regeneration, and therapeutic response. Our aim is to establish platform technologies to advance biological engineered living materials and make two proof-of-concept materials with different applications: Living Therapeutic Material (LTM) and Living Regenerative Material (LRM).

We develop skin-inspired engineered living materials for everyday

Nextskins ELM 1

Living Theurapatic Materials for Skin

Living Regenerative Materials for Protective Applications

Nextskins ELM 2

This is what we are working on.

We are generating novel living materials based on a grown matrix hosting engineered multicellular consortia that build and functionalise these different layers. Spatiotemporal patterning is realised by genetic control and the physicochemical properties of cells and biomolecules.

As a powerful strategy to accelerate the adoption of our living materials in society, we will systematically involve the potential end- users and designers in our research for the materials and product development to happen in synergy.

Living Therapeutic Material (LTM)

Our living therapeutic material is designed to be used as a wearable patch for the dynamic and responsive treatment of skin-based disorders. At its core is a hydrated layer of nanocellulose produced from safe bacteria and containing living yeast cells that respond to diffusible cues. Its top layer will consist of hydrophobic proteins and other biomolecules produced by yeasts that form an external barrier to prevent the material dehydrating when being worn.

The bottom layer is designed to interact with the wearer’s skin and their skin microbiome, containing computationally designed proteins that release signal factors to the material core when they encounter destructive enzymes like those seen during skin microbiome disorders. The three-layer material is designed to be grown from a community of engineered yeast and bacteria that are typically found in kombucha brewing. We plan to demonstrate this as a therapeutic material for treatment of atopic dermatitis.

Living Regenerative Material (LRM)

The Living Regenerative Material (LRM) is a solid composite material with high toughness and impact resistant qualities. LRM shows multifold advantages over traditional inert materials (ceramics, plastics) in protective garments. It is designed such that it can regenerate itself and achieve local self-reinforcement in mechanically stressed regions, a unique property compared to current materials and other engineered living materials (ELMs).

Further, it is based on a sustainable fabrication method, and consists of fully biocompatible nontoxic components. It is composed of biomineralized biopolymers hosting bacterial spores. The core of the LRM is arranged in microscale layers of minerals, reminiscent of the highly tough biominerals in nature (nacre, bone, dentin). LRM is encapsulated in an activator shell, engineered to prevent water penetration and to memorize local mechanical experience, providing the local self-reinforcement.

EIC

The EIC, the European Innovation Council, is an EU funding body which aims at identifying and supporting breakthrough technologies and game changing innovations with the potential to scale up internationally and become market leaders. It supports all stages of innovation from R&D on the scientific underpinnings of breakthrough technologies, to validation and demonstration of breakthrough technologies and innovations to meet real world needs, to the development and scaling up of start-ups and small and medium-sized enterprises (SMEs).

Financial support by EIC is provided through three main instruments: the ‘Pathfinder’ for advanced research on breakthrough / game-changing technologies; ‘Transition’ for transforming research results into innovation opportunities; and the ‘Accelerator’ for individual companies to develop and scale up breakthrough innovations with high risk and high impact. All EIC funded projects and companies, as well as selected applicants, have access to a range of EIC Business Acceleration Services providing access to leading expertise, corporates, investors and ecosystem actors.

Pathfinder Challenge 3: ELM:

Under the Horizon Europe programme (2021-2027) the EIC pathfinder instrument will know several so called challenges. Challenge calls are more specific than general pathfinder calls and they are likely to be a one time event. The NextSkins consortium receives funding through the EIC pathfinder challenge 3 “ELM”: Engineered Living Materials. This call has two main objectives: (1) to support the development of new technologies and platforms enabling the controlled production of made-on-demand living materials with multiple predictable dynamic functionalities, shapes and scales and (2) to build a community of researchers and innovators in ELMs through portfolio’s activities.

“We collaborate with life in the interest of planet and society”

Team Nextskins

Meet the team

Dr. Marie-Eve Aubin-Tam

Marie-Eve Aubin-Tam is leading a research group in the Bionanoscience department at TU Delft (Netherlands) since 2012. She obtained her Ph.D. in biological engineering at the Massachusetts Institute of Technology (MIT) in 2008, and then followed by a Postdoc in single-molecule biophysics also at MIT. Her expertise lies at the interface of biophysics and material science. She seeks to understand the physics and biology of living matter, and then use this knowledge to develop material with superior performance, as well as new production methods that are more sustainable. Together with her team, she pioneered the use of bacterial manufacturing of biomimetic nacre-like CaCO3 layered high-performance materials.

Prof. Markus Linder

Markus Linder is Professor in Biomolecular Materials at Aalto University. Markus worked previously as a research professor at VTT Technical Research Centre in Finland. His research has focused on protein engineering on cellulose degrading enzymes, hydrophobins, and structural proteins such as silks. A long term aim has been to use engineered proteins as components in materials and his research has through this had a strong focus on materials such as cellulose, graphene, and composites. In the NextSkins project he works on integrating protein functionalities in living materials by production in different coexisting microbial strains.

Prof. Tom Ellis

Tom Ellis is Professor in Synthetic Genome Engineering at Imperial College London. Tom has a degree in Molecular Biology from Oxford University and a PhD in DNA-binding Pharmacology from Cambridge University. Tom worked in a drug development company in London, then spent two years as a postdoc investigating synthetic biology at Boston University before starting his own group at Imperial College London. His research team develop synthetic biology and genome engineering tools for Baker’s yeast, bacteria and mammalian cells and apply these in projects to make therapeutic molecules, biological sensors and engineered living materials (ELMs).

Prof. Elvin Karana

Elvin Karana is Professor of Materials Innovation and Design at TU Delft, The Netherlands, where she founded and directs the Materials Experience Lab. Giving emphasis to materials’ role in design as experiential and yet deeply rooted in their inherent properties, Elvin explores and navigates the productive shifts between materials science and design for materials and product development in synergy. In 2019, she founded the creative biodesign research lab Material Incubator, that aims at designing materials that incorporate living organisms and exploring their potential in fostering an alternative notion of the everyday.

-

Jeong-Joo is a post-doctoral researcher at the department of Bionanoscience at TU Delft, the Netherlands. Before joining the TU Delft as a postdoc, he obtained his Ph.D. in bio-based material at Korea University, mainly coming up with the fabrication process using microbial metabolites to develop sustainable methods. In parallel, he focuses on the ecological and physiological roles of microbial metabolites in nature to get inspiration. As a member of NextSkins, he contributes to the material fabrication process and research on how to utilize bacterial cellulose and biomineralization in a very feasible way.

J.J.Oh@tudelft.nl

-

Joana Martins is an Assistant Professor in the Biodesign field at TU Delft, The Netherlands. Before joining TU Delft, in January 2022, she was an Assistant Researcher at CIIMAR, University of Porto (UP), Portugal, where she was developing her research in the Marine Biotechnology field. She is a Microbiologist with a PhD in Biology from the Faculty of Sciences of University of Porto, Portugal.

At TU Delft Joana is co-coordinating the first Biodesign courses offered by Industrial Design Engineering faculty. Her research aims to explore the potential of microorganisms, with a focus on cyanobacteria, in Biodesign aiming the ‘decrease of ecological footprint’ and ‘novel materials expressions’.

J.Martins@tudelft.nl

-

Jasper van Heusden is a project manager and research funding specialist at TU Delft for the department of Bionanoscience at the faculty of Applied Sciences. He advises and supports researchers of this department with application processes and project management. In this capacity he contributes to the managerial side of the NextSkins project.

Before joining the TU Delft in his current role, Jasper was a behavioural biologist and ecologist who did research into sexual selection using various model organisms like Cichlid fish and Damselfies. After completing his studies in Leiden and short projects scattered over Europe he settled for a PhD project on population genetics at the Universidad Complutense de Madrid, Spain, researching the genetic component of migration behaviour in song birds. He is still active in Bat research and conservation.

Jasper.Vanheusden@tudelft.nl

-

Jun Wu is an Associate Professor of Design Engineering at TU Delft, The Netherlands. Before joining TU Delft in Sep. 2016, he was a Marie Curie postdoc fellow at the Department of Mechanical Engineering, DTU Denmark. He obtained his Ph.D. in Computer Science in 2015 from TU Munich, Germany, and a Ph.D. in Mechanical Engineering in 2012 from Beihang University, China.

Jun's research is focused on computational design and digital fabrication, with an emphasis on topology optimization (which is sometimes referred to as generative design). His work received best paper awards at international conferences including the Symposium on Solid and Physical Modeling 2019, and the World Congress of Structural and Multidisciplinary Optimization 2019. He received the SMA Young Investigator Award from the Solid Modelling Association in 2021. He is on the editorial board of Computer-Aided Design (Elsevier) and Structural and Multidisciplinary Optimization (Springer).

J.Wu-1@tudelft.nl

-

Ward Groutars is a designer and researcher with a fascination for biology and a passion for combining different creative techniques. During his studies, Ward specialised in Biodesign, collaborating with living organisms in the development of novel materials and products. By swapping the workshop for a laboratory, he got acquainted with microbiological techniques and methods as well as various species of bacteria and algae. After his studies, Ward worked as a researcher on the Coloured by Flavo project, where he investigated the structural colour produced by Flavobacteria and the potential that these offer for interaction design. This culminated in the development of a living interface in which the dynamic colourations of these bacteria inform human viewers on various environmental or digital factors. In his upcoming PhD. research, Ward will focus on the notion of symbiosis in Biodesign and how this might affect the role of the designer.

-

Ivy is a PhD student in Prof Tom Ellis’ group in the department of Bioengineering at Imperial College London. Her research interest prioritises engineering novel genetic pathways to functionalise cellulose produced by Komagataeibacter spp. bacteria.

Prior to starting her PhD, Ivy worked for the NextSkins industrial partner Modern Synthesis, a biomaterial innovation company. In her past role as a Scientist, she helped develop Modern Synthesis’ proprietary biofabrication platform using materials from bacteria to produce a new class of cellulose-based textiles and composites to displace petrochemical dependence.

-

Verindi Vekemans is a PhD candidate at the department of Industrial Design at TU Delft, The Netherlands. She works within Elvin Karana’s Material Experience Lab and will be involved in researching and designing with living regenerative skins. The goal of her PhD research is to develop generative design tools for bio-designers. Before starting her PhD, she obtained her bachelor’s and master’s degree in Industrial Design at the Eindhoven University of Technology, in which she has focused on shape-changing interfaces, interactive soft materials and 3D printing.

V.C.Vekemans@tudelft.nl

-

Franka van der Linden will be a postdoctoral researcher at the TUDelft starting February 2023. Within the NextSkins project she will join the research on self-healing materials, more specifically on the proteins within the material. Currently she is working on finishing her PhD at the University of Amsterdam, on the development of genetically encoded biosensors for quantitative imaging of calcium concentrations within living cells. Franka obtained her bachelor’s degree in Life, Science and Technology at the universities of Delft and Leiden, followed by a master in Molecular Life Sciences at the Wageningen UR.

-

Likhitha Kummetha is a PhD candidate in Marie-Eve Aubin-Tam’s group in the department of Bionanoscience in TU Delft, the Netherlands. She completed her master’s in the department of Chemical Engineering in TU Delft with focus on product engineering.

During her master’s, she worked to develop microfluidic aptamer based optical biosensor for quantification of cytokines in sweat. Prior to this, she obtained her bachelor’s in Chemical Engineering and Material Science from BITS Pilani, India.

In her PhD, she is working on the fabrication of self-healing nacre-like biocomposites made of bacterial cellulose and microbially precipitated biominerals.

L.R.Kummetha@tudelft.nl

-

Karoliina Elfving is a PhD student in Professor Markus Linder’s Biomolecular Materials research group at Aalto University. Karoliina has a background in microbiology, which she studied in University of Helsinki. Karoliina completed her master’s thesis in Markus’ research group where she developed an in vivo screening system for peptide-protein pairs to improve the rate of protein ligation.

In the NextSkins project her focus will be in creating and optimizing an expression of a fusion protein in yeast to develop a hydrophobic outer layer for living materials.

-

Salla Koskela is a post-doctoral researcher in Professor Markus Linder's group at Aalto University, Finland. She obtained her Ph.D. in biotechnology in 2022 at KTH Royal Institute of Technology, Sweden, focusing on enzymatic production of nanocellulose and cellulose-based materials.

Her M.Sc. and B.Sc. degrees are from University of Helsinki, where she studied fungal biotechnology. Her key areas of expertise are protein production in fungal hosts, carbohydrate-active enzymes, and the use of enzymes and proteins in fabrication of materials such as hydrogels and films. As a member of the NextSkins project, she contributes to the fabrication of multi-layered engineered living materials (ELMs) that take advantage of the robust natural polymers silk and cellulose as a scaffold for living cells.

For this aim, she is expressing engineered enzymes and proteins in yeast that can be utilized for the assembly of the layers and to enhance the barrier properties of the outer layer.

-

Koray Malci is a postdoc researcher in the Ellis Lab at Imperial. He obtained his bachelor's and master's degrees from Istanbul Technical University, where he studied molecular biology, genetics and biotechnology. His PhD at the Bioengineering Department at the University of Edinburgh saw him designing yeast cell factories using novel genome editing tools to produce early-step Taxol precursors.

In the NextSkins project, he works on microbial strain design using synthetic biology to develop microbial consortia-generated engineered living materials. To do this, he is developing modular genetic toolkits and automation methods to engineer yeast strains, cellulose-producing bacteria and Bacillus subtilis.

Previous contributors

-

Rahul is an Academy Research Fellow (Junior PI) in Professor Markus Linder’s group at Aalto University. He obtained his D.Sc. (Technology) in Bioengineering in 2015 from Tampere University (then Tampere University of Technology) for his research works on biological hydrogen production.

Since procuring the Postdoctoral grant from The Academy of Finland (an agency within the administrative branch of the Finnish Ministry of Education, Science and Culture) in 2019, Rahul’s prime research focus has been on developing sustainable bioprocesses and genetic engineering tools for bacterial nanocellulose producing bacteria. In 2022, he was awarded the Academy Research Fellow grant.

The project, on-going at Aalto University, focusses in studying the fundamental genetic facets of protein secretion in Komagataeibacter spp. to develop ‘smart’ functional material for microplastic depolymerization.

In the NextSkins project, Rahul will be collaborating as a supporting member.

-

Raphael is a postdoctoral researcher and designer engaged in critical explorations of bio-technology in the field of Human-Computer Interaction (HCI): Through making, growing, writing, and speculating, Raphael strives to continue unpacking the social and cultural implications of considering living agents – namely microbes – as computational materials for interaction. Following his Master’s in Design Interactions from Royal College of Art in London, Raphael gained his PhD from Queen Mary University of London. His thesis (2020), titled Effects of Microbial Integration on Player Experiences of Hybrid Biological Digital Games, investigated ways in which distinct microbial materiality could be harnessed into design processes towards enhancing playful experiences of human-computer interaction. Outcomes of the research, along with his latest studies on viruses and DNA, have been published at major international academic venues, including ACM CHI.

-

Ramon van der Valk is a research technician and lab manager at TU Delft for the department of Bionanoscience in the Netherlands.He obtained his Ph.D. at Leiden University for work combining molecular genetics, biophysics, and biochemistry. Having come into contact with multiple different fields he can understand how they can not only synergise beautifully, but also clash in their respective perspectives. Using his previous interdisciplinary insights he will be playing a supporting role in the NextSkins project, helping where necessary to smooth the incorporation of new ideas and provide insights, expertise, and techniques to aid in overcoming hurdles.

R.A.VanderValk@tudelft.nl

Advisory board

NEXTSKINS is supported by an advisory board consisting of people and companies from a wide array of disciplines and with varying expertise. They provide advice and feedback on all aspects of the project to aid NEXTSKINS to reach its full potential and maximise impact and output. Here are some, but not all of our advisory board members.

-

Ben is the co-founder and CTO of Modern Synthesis, a London based biomaterial company growing the next generation of materials for the fashion industry.

The company works at the interface of design, biology and materials science and is interested in functional, responsive and high performance materials that are also truly sustainable. Nextskins is a hugely exciting project at the cutting edge of this effort.

Ben completed his PhD in synthetic biology and biopolymer production in the Prof. Tom Ellis lab at Imperial College and was previously CTO of a materials spin out company Puraffinity.

-

Dr. DirkJan Hijnen earned his MD at the University of Utrecht after he received an MSc degree in Biomedical Sciences from the University of Amsterdam. He went on to earn his PhD from the University of Utrecht, studying the role of T-cells in the pathogenesis of atopic dermatitis.

During his dermatology residency he continued his research and received a grant to continue his research on skin T-cells in atopic dermatitis skin in the laboratory of Rachael A. Clark at the Brigham and Women’s Hospital in Boston, MA.

From 2011-2017 Dr. Hijnen worked at the University Medical Center of Utrecht. Since August 2017 Dr. Hijnen is working at the Erasmus MC in Rotterdam as a dermatologist, instructor and researcher. Dr. Hijnen is leading the center of excellence for patients with atopic dermatitis. His research focuses on the development of new ways to characterize atopic dermatitis patients, by integration of clinical, serological, cellular and molecular biomarkers. This will lead to a better understanding of disease mechanisms and contribute to precision medicine.

Dr. DirkJan Hijnen is a board member of the Dutch Society for Dermatology and Venerology, past-president of the Dutch Society for Experimental Dermatology, board member of the International Society for Atopic Dermatitis (ISAD), the International Eczema Council (IEC), and the EADV Task force for Atopic Dermatitis. Dr. Hijnen serves as a scientific advisor for BIOMap, ImmuneHealth Holland XL, NextSkins project, Dutch Science and Innovation council, and Dutch Research Agenda.

-

Rob Gathercole is the Research Director in the Product Innovation team at lululemon, a yoga-inspired technical apparel and well-being brand. He obtained his Ph.D. in Applied Sport Science at the University of Victoria (Canada) in 2014, and has worked in innovation around sports technology, apparel, and wellbeing since 2009.In his current role, he leads research focused on apparel innovation, overseeing research activities spanning early-stage foundational science through to its application in concept development.

His technical expertise lies in human performance, neuromuscular fatigue, and thermophysiology, but he has also led research across broad domains such as biomaterials, immersive technologies, and the microbiome.

-

David Breslauer is the co-founder and Chief Technology Officer of Bolt Threads. Bolt Threads invents cutting-edge materials for the fashion and beauty industries to put us on a path toward a more sustainable future.

There, David leads the research and development teams, focused on Bolt’s two breakthrough and commercially available products: Mylo, a mycelium-based leather alternative, and b-silk, a recombinant protein-based silicone elastomer alternative.

David obtained his PhD in Bioengineering at UC Berkeley and UCSF, and B.S. in Bioengineering from UC San Diego. David is an Advisory Board Member for NextSkins.

-

Sencha Van Kinderen is Sr. Product Technologist Medical Devices at Danone Nutricia Research. He obtained his Master degree Industrial Design Engineering (IPD) at the TU Delft (The Netherlands) in 2005.

His expertise lies within health innovation and product realisation of medical devices and services. Being the link between end-user and big industry he can direct the design considerations from cradle to grave, directly impacting people and planet on large scale.

Passionate about making his part of the health industry sustainable he got involved in this exiting NextSkins study for ground-breaking materials.

-

Associate Professor, David Peck, researches and teaches in the field of circular built environment and critical materials, based in the faculty of Architecture and the Built Environment. He is a founding member of the Circular Built Environment Hub.

David is also Honorary Associate Professor with University College London – The Bartlett and an adjunct Professor at MIP Politecnico di Milano, Graduate School of Business. David works with ad hoc committees in the EU, Brussels, and is an H2020 & Horizon Europe reviewer.

He is the TU Delft lead scientist for EU Horizon Europe & Horizons 2020 projects CiRCLETECH, Pop Machina, ProSUM, ERN and FP7 CRM_Innonet.

David is TU Delft scientific leader for the EU KIC EIT Raw Materials & EIT Manufacturing, representing the university in the programme. He leads a number of projects in these important programmes that has a focus on critical materials and circular economy, in particular Remanufacturing.

David is an Executive Board Member for EIT Raw Materials and ERMA.

Main Work Packages

-

We will use the latest advances in synthetic biology to enable microbial cells to produce a new generation of functional and responsive Engineered Living Materials.

Using our expertise in synthetic biology and genome engineering, we will develop standardised and automated methods for designing, building and optimising DNA-encoded genetic programs that are written to direct bacteria and yeast to make and modify materials.

The latest advances in modular DNA cloning, cell-to-cell signalling, optogenetics and open-source robotics will be used to advance DNA-based engineering in multiple organisms that will be used to produce our Engineered Living Materials.

-

To achieve different materials functionalities on our Engineered Living Materials we will use structurally engineered proteins. These proteins are produced within the living materials by microbes developed in WP1.

Proteins such as hydrophobins can act as coatings that give protective and water-repelling properties to the materials. Inspiration for these is taken from fungi which use hydrophobin-proteins as protective coatings. Spider-silk proteins will be used to achieve mechanical properties in the living material.

-

The Living Therapeutic Material (LTM) and Living Regenerative Material (LRM) will be generated using the strains engineered in WP1 and the protein constructs optimized in WP2.

Both LTM and LRM are designed to be arranged in layers having specific cellular and molecular compositions, leading to dedicated functions.

We will quantitatively investigate the structure and arrangement of these layers, as well as assess their specialized tasks (sensing, therapeutic, mechanical or regenerative).

The fabrication procedure and any processing method will be optimized for improved materials performance, based on the structural, mechanical and biological characterization.

-

In this WP we will focus on biodesign and the social implications of our NextSkins materials.

We will prototype and explore user experience of Living Therapeutic Materials.

We will develop biodesign tools for predictive exploration of the design space with Living Regenerative Materials.

Background publications

Dr. Marie-Eve Aubin-Tam

Scalable bacterial production of moldable and recyclable biomineralized cellulose with tunable mechanical properties.

Dr. Marie-Eve Aubin-Tam

Bioprinting of regenerative photosynthetic living materials.

Dr. Marie-Eve Aubin-Tam

Bioproduced polymers self-assemble with graphene oxide into nanocomposite films with enhanced mechanical performance.

Prof. Markus Linder

Recombinant protein condensation inside E. coli enables the development of building blocks for bioinspired materials engineering – Biomimetic spidersilk protein as a case study.

Read publication online

Download publication PDF

Prof. Markus Linder

Self-Assembled Hydrophobin Protein Films at the Air-Water Interface: Structural Analysis and Molecular Engineering.

Prof. Markus Linder

Biomimetic composites with enhanced toughening using silk-inspired triblock proteins and aligned nanocellulose reinforcements.

Download publication PDF

Prof. Tom Ellis

Living materials with programmable functionalities grown from engineered microbial co-cultures.

Prof. Tom Ellis

Bacterial cellulose spheroids as building blocks for 3D and patterned living materials and for regeneration.

Prof. Tom Ellis

Komagataeibacter Tool Kit (KTK): A Modular Cloning System for Multigene Constructs and Programmed Protein Secretion from Cellulose Producing Bacteria.

Read publication online

Download publication PDF

Prof. Dr. Elvin Karana

Material Driven Design (MDD): A Method to Design for Material Experiences.

Prof. Dr. Elvin Karana

Living Artefacts: Conceptualizing Livingness as a Material Quality in Everyday Artefacts.

Prof. Dr. Elvin Karana

Flavorium: An Exploration of Flavobacteria’s Living Aesthetics for Living Color Interfaces.

Nextskins publications

SubtiToolKit: a bioengineering kit for Bacillus subtilis and Gram-positive bacteria

Download publication PDF

Living Artefacts for Regenerative Ecologies

Download publication PDF

Leveraging the Versatile Properties of Bacterial Spores in Materials

Download publication PDF

Surfacing Livingness in Microbial Displays

Download publication PDF

Designing Living Artefacts for Multispecies Interactions

Download publication PDF

Living artefacts for regenerative ecologies

Download publication PDF

EIC ELMs Portfolio

NEXTSKINS is part of a portfolio of projects funded under the Engineered Living Materials Pathfinder Challenge by the European Innovation Council and started on November 2022

Please check out https://eic.ec.europa.eu/eic-portfolios/health_en#engineered-living-materials-elms where all the projects in the portfolio are listed and where a link to the portfolio’s output is provided.

With this Pathfinder ELMs Challenge the EIC seeks to seize the opportunity to position strategically Europe at the forefront of the ELMs field. This Pathfinder Challenge aims to overcome the technological challenges to harness the engineering potential of nature for materials’ production. The specific objectives of Pathfinder ELMs Challenge are to support the development of new technologies and platforms enabling the controlled production of made-on-demand living materials with multiple predictable dynamic functionalities, shapes and scales; and to build a community of researchers and innovators in ELMs.

ELMs projects funded from the EIC Open calls actively contribute to the Portfolio activities with the aim to advance the scientific and technological development of ELMs and promote its dissemination across Europe, increase the visibility of the ELMs community internationally by sharing knowledge and building partnerships, engage with regulatory bodies to address ELMs portfolio needs, address ethical, legal and social aspects through early engagement with policymakers and the public, and to assess and address the need for standardization in the ELMs portfolio, identify barriers to the adoption and commercialization of ELMs and engage with stakeholders, guided by responsible research and innovation methods.”

“NEXTSKINS” is part of a portfolio of projects funded under the Engineered Living Materials Pathfinder Challenge by the European Innovation Council and started on November 2022.

List of projects:

-

Coordinator: CNR (IT)

Project partners: 7

Key-words: Bio-hydrogels, Bactoinfection, Liposome, Phages, Hard tissue regeneration, Processing technologies

Project description: BIOACTION aims at developing a new methodology in implant technology based on functionalized bio-hydrogels that will convert the negative occurrence of biofilm-associated infections, the primary cause of implant infections and failure, into a positive resource.

The main goal of BIOACTION is to transform implant-associated bacteria for the programmable production of specific proteins for in vivo cell recruitment and tissue regeneration, exploiting gene sequences loaded on engineered liposomes and phages, bound to hydrogel scaffolds. BIOACTION will develop new biomimetic substrates that can transform biofilm into extracellular matrix for the regeneration of target tissues. It will establish a high versatile technology to be used as injectable materials and implant coatings for periodontal and peri-implant infection treatments.

The proposed approach will be validated in two clinically relevant animal models: dental implant and permanent transcutaneous bone. BIOACTION, would radically advance the future of infection treatment by revolutionizing the classical approaches leading to the improvement of state of care, health outcomes and to achieve huge socio-economic benefits. The project is strongly interdisciplinary in nature involving expertise biomaterials, synthetic biology, phage and liposome technology, medicine.

-

Coordinator: University of Trento (IT)

Project partners: 4

Key-words: Synthetic Biology, Artificial Cell, 3D Bioprinting, Microfluidics, 3D cell culture

Project description: Bio-hybrid materials and physiochemical interactions hold great promise for advancing the pharmaceutical and chemical sectors. However, current developments in these technologies are limited, with few functional options available. In this context, the EIC-funded Bio-HhOST project aims to develop a bio-hybrid material composed of living and artificial cells, enabling a wide range of interactions.

The incorporation of artificial cells will facilitate the proliferation, function, and differentiation of living cells, while also possessing functional metabolisms capable of revolutionising the sector through chemical interactions. Additionally, the project employs 3D tissue models and simulations to enhance the understanding of the material and its response to diseases, thereby reducing the necessity for animal research.

-

Engineering a swimming bio-robot and a living human mini-heart.

Coordinator: University of Twente (NL)

Project partners: 4

Key-words: tissue engineering, biosensing, stem cells, cardiovascular diseases, physiology

Project description: Manufacturing our very own hearts is just a heartbeat away, literally. Engineers are joining forces with biologists to make biological heart robots. The EU-funded BioRobot-MiniHeart project is developing a vascularised beating mini-heart. In parallel, the team is designing a self-propulsion swimming bio-robot created by assembling human cardiac cells into 3D tissue structures; using sacrificial moulding and high-resolution 3D bioprinting.

The mini-heart and the bio-robot will provide scientists with a more realistic human cardiac model in vitro and an appropriate tool to assess cardiotoxicants’ presence in the environment. We expect this innovation to help speed up the development of heart disease cures.

-

Combining fungi and bacteria into novel biomaterials

Coordinator: Royal Danish Academy – Architecture, Design, Conservation (DK)

Project partners: 6

Key-words: bacteriology, synthetic biology, mycology

Project description: Engineered living materials (ELMs) are composed of living cells endowed with unique properties and functions. ELMs have received significant attention in materials sciences due to their tuneability and potential for sustainable production. Funded by the European Innovation Council, the Fungateria project aims to generate an innovative portfolio of ELMs that combine fungi with bacteria.

Growing the vegetative part of the mushroom—the mycelium—on different organic substrates is the most common way of producing fungi-based materials. The project will combine the mycelium with bacteria that serve as a chassis for sensor-containing genetic circuits. The resultant ELMs will exhibit advanced functionalities and inducible degradation when no longer needed.

-

Implantable Ecosystems of Genetically Modified Bacteria for the Personalized Treatment of Patients with Chronic Diseases.

Coordinator: SILK BIOMED S.L.

Project partners: 6

Key-words: GEB, ELM, silk fibroin, micro bioreactor, chronic diseases, aged-related macular degeneration

Project description: ISOS is pioneering the development of a groundbreaking biomedical solution: a bioreactor housing genetically engineered probiotic bacteria (GEB) within biomaterials. This innovation is aimed at chronic diseases requiring extended treatments. Encapsulated GEB populations synthesize therapeutic molecules in response to patient-specific signals such as inflammation or reactive oxygen species.

Designed to maintain dynamic equilibrium and ensure GEB survival within the pathological environment, ISOS offers personalized treatment through in-silico tools and synthetic biology. As a Proof-of-Concept, ISOS plans to deploy an implantable GEB-based bioreactor for treating wet age-related macular degeneration (wAMD). This advancement aims to replace frequent Anti-VEGF injections with a single bioreactor, enhancing therapeutic efficacy and minimizing side effects. ISOS pioneers a new therapeutic approach using recombinant probiotic libraries, promising precise local drug production and efficient delivery tied to dynamic pathological cues.

-

Fungi-based engineered living materials with controllable properties.

Coordinator: Albert Ludwigs University of Freiburg (DE)

Project partners: 5

Key-words: Mycology, electrical engineering, sensors

Project Description: Fungi comprise approximately 100 000 described species to date. The real total is estimated to be in the millions. They are amazing factories, producing numerous bioactive metabolites of therapeutic interest.

The EU-funded LoopOfFun project has recognised their potential in yet another innovative area – as part of engineered living materials (ELMs), with open- and closed-loop control of mechanical and structural properties.

The project will identify fungi gifted with superior abilities for materials synthesis and harness them for synthetic biology-based programming. The programming will be accomplished via a novel automatic robotised platform to develop the fungi into ELMs based on iterative design-build-test-learn cycles. The outcomes will then support the rational design of such materials.

-

Living therapeutic and regenerative materials with specialised advanced layers.

Coordinator: Delft University of Technology (NL)

Project partners: 3

Key-words: bacteriology, dermatology, biomolecules, ceramics

Project Description: Compared to conventional materials, biomaterials in living organisms possess specific architecture and organisation: and often exhibit multiple functions. Εngineered living materials (ELMs) have emerged at the junction of synthetic biology and material science to produce materials with improved functionality because of the living organisms within them.

Funded by the European Innovation Council, the NextSkins project is inspired by the structure and function of the many layers of skin. Researchers will mimic the specialised skin arrangement to make two engineered living materials: one with a therapeutic role to treat skin diseases and one with a purpose to be used as a protective garment in sports.

-

Living tissue manufacturing using symbiotic materials

Coordinator: IN society (IT)

Key-words: bacteriology, stem cells, bioprinting,

Project Partners: 6

Project Description: The EU-funded PRISM-LT project will use a hybrid living materials concept to create a flexible platform for living tissue manufacturing.

The innovative bio-ink will contain stem cells integrated into a supporting matrix with engineered helper bacteria or yeast cells. The bioprinting process will produce a 3D patterned structure where stem cells could be induced to differentiate into different lineages. The directed stimulation of differentiating stem cells will force them to produce lineage-specific metabolites for sensing by the designer helper cells. The helper cells within the platform will then enhance localised lineage commitment to sustain differentiation stability.

The project aims to implement this strategy for the development of two symbiotic materials designed for biomedical and food applications, respectively.

-

Archibiome tattoo for resistant, responsive, and resilient cities

Coordinator: InnoRenew CoE (SI)

Key-words: microbiology, architecture, biofabrication, microbiome

Project Partners: 6

Project Description: The REMEDY project pioneers the archibiome tattoo - a living, bespoke layer for buildings that enhances both, aesthetics and functionality. By integrating advances in microbiology, synthetic biology, and materials science, REMEDY develops engineered living materials and specialized biofabrication process for personalized architectural design.

At the core of REMEDY’s approach are tailored microbial consortia formulated into innovative microbial inks that function like probiotic skincare. These living consortia establish a resilient microbiome on building surfaces, providing pathogen protection, supporting carbon sequestration, producing oxygen, and enabling bioremediation. Funded by the European Innovation Council, REMEDY brings metabolic thinking into sustainable design, advances probiotic architecture, and drives a microbial revolution to reshape the perception of microorganisms in the built environment.

-

www.supervised-morphogenesis.eu

Supervised morphogenesis in gastruloids as an alternative to conventional single-tissue organoids.

Coordinator: Oslo University Hospital (NO)

Project partners: 7

Key words: artificial intelligence, developmental biology, stem cells, physiology

Project Objectives: The lack of realistic in vitro organ models that faithfully represent in vivo physiological processes is a major obstacle affecting the biological and medical sciences. The current gold standard is animal experimentation, but it is increasingly evident that these models mostly fail to recapitulate human physiology. Moreover, animal experiments are controversial, and it is a common goal in the scientific community to minimise the use of animals to a strictly necessary minimum.

The emergence of stem cell-engineered organ models called organoids represents the only viable alternative to animal research. However, current organoid technology is yet to produce the larger physiologically relevant organ models that the medical sciences need. Specifically, current organoids are too small, not vascularised and lack the 3-dimensional organisation found in vivo.

In this interdisciplinary project, we aim to challenge all these limitations using the recently developed gastruloid technology guided by cutting-edge bioengineering and artificial intelligence.

Gastruloids are formed by initiating the very early developmental processes and develop along a highly coordinated three-axial process that closely resembles mammalian embryogenesis. They can establish several organ precursors simultaneously, thus constituting relevant improvements over conventional single-tissue organoids.

To harvest the potential of gastruloid technology, we will first implement extensive sequencing and imaging experiments to optimise the developmental trajectory of gastruloids for organ inductions. We will then build these datasets into a multimodal data matrix to identify gastruloid candidates for cardiovascular and foregut development. Candidates with substantial vasculogenesis will be chosen for later vascularisation by anastomose with endothelial cells.”

Downloads:

Updates:

November 2023 – ELMs Portfolio Unveils Comprehensive Strategic Plan

A milestone within the EIC ELMs portfolio has been reached: the official Strategic Plan for ELMs, created by our Programme Manager and Project Officer is now available. The Strategic Plan outlines key activities, providing a roadmap to transform ELM technologies into impactful innovations. It reflects our commitment to effective portfolio management, ensuring our groundbreaking research translates into real-world solutions.

EIC-EMA Workshop on the Regulatory Framework of ELMs (2025)

On February 6, 2025, we were thrilled to see several pioneering projects from the EIC ELMs Portfolio—PRISM-LT, -LoopOfFun-ELMs, NextSkins, Bio-HhOST, BioRobot-MiniHeart, ISOS Project EU, Bioaction EU, REMEDY —participate in the EIC-EMA Workshop on the Regulatory Framework of Engineered Living Materials (ELMs).

Co-organized by the European Innovation Council (EIC) and the European Medicines Agency (EMA), this workshop served as a vibrant exchange platform for ELM researchers to explore regulatory challenges. These innovative materials are set to transform medicine and biotechnology, marking a critical milestone for ELMs in Europe.

With keynotes from Barbara Gerratana (EIC), Orsolya Symmons (EIC), and @Costantinos Ziogas (EMA), the event ignited insightful discussions. The panel, co-moderated by Falk Ehmann (EMA) and Laura Martinelli (PRISM-LT, INsociety), delved into essential topics like:

🔍 ELM product classification and approval pathways

🛡️ Safety and compliance requirements

🔬 Clinical trials for bioprinted and engineered tissues

📜 EMA’s guidance on ATMPs

This interactive session encouraged a plethora of questions and underscored the imperative for ongoing regulatory dialogue as ELM technologies continue to evolve. The workshop provided valuable insights into the changing regulatory landscape, highlighting the necessity for continuous collaboration among innovators, regulatory bodies, and industry stakeholders.

Engineered Living Materials Portfolio year 2 progress report (2024) and year 3 plans (2025)

Discover the progress made by the EIC ELMs Portfolio in advancing living materials technology and shaping Europe’s leadership in this field. This report highlights key achievements since the 2023 strategic plan and outlines the objectives for the third year of the Portfolio.

EIC ELMs Second Annual Meeting (Sept 2024).

The EIC ELMs portfolio held its second annual meeting on September 18 in Saarbrücken, Germany. There were 140 attendees, including 33 representatives of the EIC ELMs portfolio projects BioRobot-MiniHeart, Bio-HhOST, Fungateria, NextSkins, LoopOfFun and Sumo, and participants of the 4th International Conference on Engineered Living Materials including recent awardees of the Programme priority in ELMs of the German Research Foundation.

It was a day of exciting science, opportunities to launch collaborations and a unique occasion to showcase the EIC ELMs portfolio projects to the ELMs community. Several members of the EIC ELMs Portfolio including EISMEA representative attended the 4th International Conference on Engineered Living Materials. The EIC had a stand at the conference that was used to showcases material and microfluidics samples from LoopOfFun, Fungateria, NextSkins and Bio-HhOST projects.

The EIC ELMs Portfolio Video thanks to the Horizon Results Booster (2024)

Discover how each project in the EIC ELMs portfolio aims to develop cheaper and more sustainable materials using living materials in a new video by Horizon Results Booster (a free service of the European Commision). The projects are pushing the technological boundaries in developing ELMs working together to overcome challenges and position Europe’s ELMs at the forefront of scientific and technological developments in the field.

EIC ELMs promotional video

At the third annual portfolio meeting, which was held in Slovenia, the EIC created a new video to showcase all research consortia connected to the ELM theme. For more information, please visit the official EIC website at https://eic.ec.europa.eu/eic-portfolios/health_en#engineered-living-materials-elms

Engineered Living Materials Portfolio Brochure (2024)

Discover why the European Innovation Council (EIC) is prioritizing portfolio management to boost Europe’s technological autonomy. Learn which are the projects in the portfolio working on common research interests and challenges to increase the chances of success.

EIC ELMs 1st Annual Meeting (Jan 2024)

The first Annual Meeting has held on 17/01/2024 at the EISMEA HQ in Brussels, Belgium. Attendance was 30 in person participants and a consistent presence online of 30 participants until the end. Representatives from Bio-HhOST and Enlight, two Open projects, attended the event in person, while online there were representatives from CyGenTiG, another Open project, and 4 staff from EMA.

News

Here’s where we’ll keep you updated on our latest developments, breakthroughs, and behind-the-scenes insights. We’ve just published our first article—and there’s more to come. Stay tuned as we continue to share what we’re working on, the progress we’re making, and the ideas driving the future of sustainable skin-inspired materials.